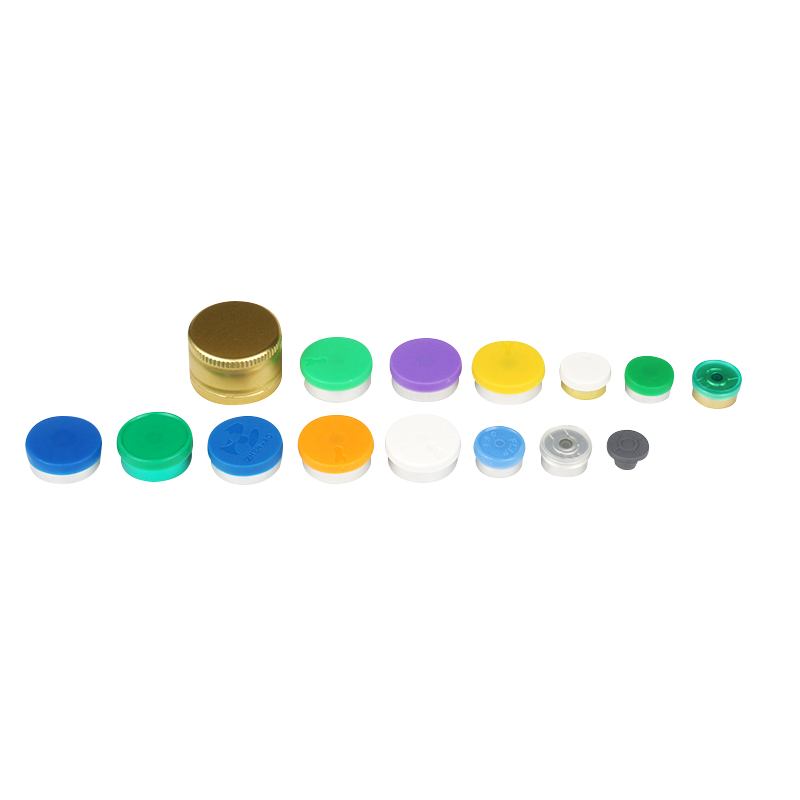

Glass Plastic Dropper Bottle Caps for Essential Oil

The dropper cap has a unique advantage, and droppers are usually made of glass or plastic, depending on the product's needs and usage. Plastic droppers are lightweight and common, while glass droppers have better resistance to chemical corrosion. The design of the dropper allows users to accurately control the distribution and release of liquids, allowing them to accurately drip or squeeze liquids, suitable for liquid products that require precise doses.

Having good sealing performance, the dropper cover can effectively prevent liquid leakage and overflow, thereby maintaining the cleanliness and safety of the product.

1. Shape: glass pipettes, aluminium screw closure, silicone teats.

2. Material: PP, glass, silicone.

3. Neck Size: 18/400 20/400 22/400 18/410 22/410.

4. Packaging: 1400PCS/CTN(customize) 12.3/11.5kg 50*38.5*27cm(30ml)(customize), export carton with shipping mark with plastic pallet.

5. Usage: glass dropper for essential oil or tea tree oil.

The dropper of the dropper cap is usually made of high-quality raw materials, such as glass, polyethylene, polypropylene, etc. These materials have durability, high transparency, and chemical stability. The glass dropper process we produce includes injection molding, glass blowing, and other specific processes. Strict control is implemented over the production process, and not only that, but also strict quality testing is carried out during and after the production of dropper caps, including visual inspection, dimensional measurement, sealing testing, etc., to ensure that the products meet high quality standards.

The application of dropper caps is extensive and clear, and they have their own place in laboratories, medical industry, pharmaceutical industry, beauty, essential oils, and other fields. Users can use the unique design of dropper caps in various scenarios for precise liquid dispensing.

We use professional cardboard box corner packaging to ensure that the product is not damaged during transportation. We add cushioning materials to the cardboard box packaging to provide additional protection for the product, fully considering the needs of leak proof, shockproof, and anti drop for users.

We provide users with complete after-sales service and clear product instructions to help them use the dropper cover accurately. We also provide telephone and online support to answer any questions users may have during the use of the product. Regularly collecting user feedback and suggestions on products is an important process for us to adjust product design and production processes in a timely manner, improve and innovate products, and thereby improve the overall quality of products and user satisfaction. We support multiple payment settlement methods to meet the needs of our customers.

Overall, we conduct comprehensive management and monitoring of the production, quality control, use, and after-sales service of dropper caps to ensure the provision of high-quality, safe, and reliable products to users.