Continuous Thread Phenolic and Urea Closures

The main material of phenolic seals is phenolic resin, which is a thermosetting plastic known for its heat resistance and strength. On the other hand, urea seals are made of urea formaldehyde resin, which has similar but slightly different characteristics as phenolic seals.

Both types of closures are designed with continuous threads to ensure a tight fit to the corresponding container neck, facilitating opening and closing. This thread sealing mechanism provides a reliable seal to prevent leakage or contamination of the contents in the container.

1. Material: Seals are usually made of phenolic or urea resins

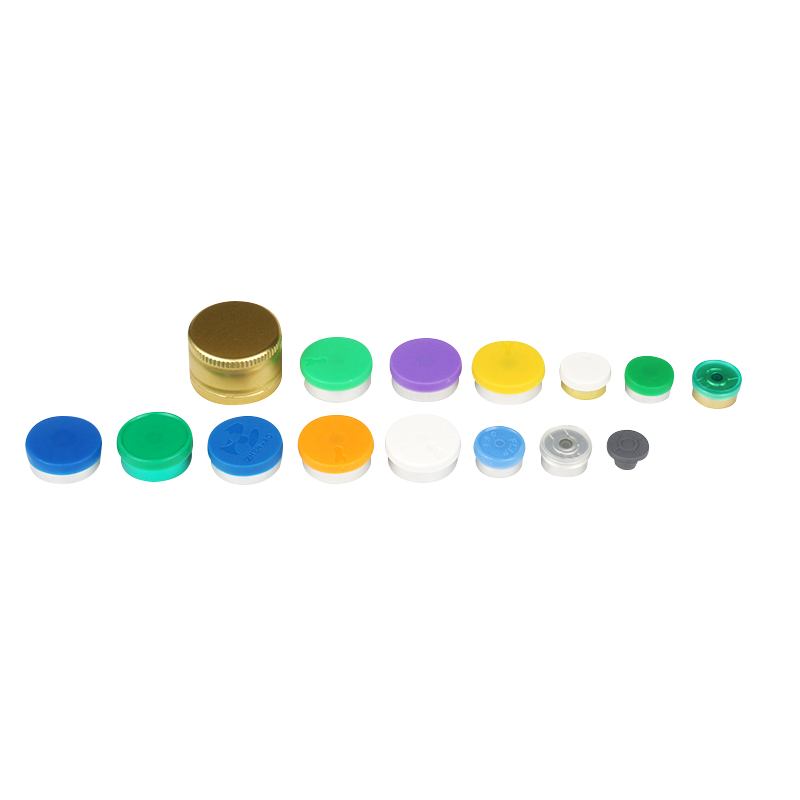

2. Shape: The closure is usually circular to accommodate the neck design of various containers. The cover usually has a smooth appearance. Some specific sealing components have holes at the top and can be combined with diaphragms or droppers for use.

3. Dimensions: "T" Dimension (mm) - 8mm/13mm/15mm/18mm/20mm/22mm/24mm/28mm, "H" Measurement in Inches - 400 Finish/410 Finish/415 Finish

4. Packaging: These closures are typically manufactured in bulk production and packaged in environmentally friendly cardboard boxes to ensure safety during transportation and storage.

Among continuous threaded phenolic and urea seals, phenolic seals usually use phenolic resin as the main raw material, while urea seals use urea formaldehyde resin. Possible raw materials may include additives, pigments, and stabilizers to improve the overall stability of the material.

Our production process for continuous threaded phenolic and urea seals includes mixing raw materials - fine phenolic or urea resin mixed with other additives to form the required mixture for seals; Forming - injecting a mixture into a mold through processes such as injection molding or compression molding, and applying appropriate temperature and pressure to shape it into a closed part after molding; Cooling and Curing - The formed closure needs to be cooled and cured to ensure that the closure can maintain a stable shape and structure; Processing and Painting - Depending on customer or production needs, closed parts may require processing (such as removing burrs) and painting (such as coating protective layers).

Our products must undergo strict quality testing to ensure that all products comply with relevant standards and regulations. The testing items include size testing, shape testing, surface smoothness testing, sealing performance testing, etc. Visual inspection, physical performance testing, chemical analysis, and other methods are used for quality inspection.

The sealing components we produce are usually packaged in bulk for easy transportation and storage. We use eco-friendly cardboard boxes for packaging, which are covered or padded with anti drop and earthquake resistant materials, with multiple layers of protective measures to prevent damage and deformation.

Providing satisfactory after-sales service to customers is a crucial aspect. We provide our customers with comprehensive services, including pre-sales, in sales, and after-sales services. If customers have any questions about the quality, performance, or other issues of our seals, they can contact us online, via email, or other means. We will respond promptly and provide solutions.

Regularly collecting customer feedback is an important way to improve products and innovate production. We also welcome all users to provide us with reasonable feedback on our products at any time, which is more in line with customer feedback. We will improve our production process. Continuously adjust and improve production quality and after-sales service to meet customer needs and expectations.

| GPI Thread Finish Comparison Chart | |||

| "T"Dimension(mm) | "H"Measurement in Inches | ||

| 400 Finish | 410 Finish | 415 Finish | |

| 8 | / | / | / |

| 13 | / | / | 0.428-0.458 in |

| 15 | / | / | 0.533-0.563 in |

| 18 | 0.359-0.377 in | 0.499-0.529 in | 0.593-0.623 in |

| 20 | 0.359-0.377 in | 0.530-0.560 in | 0.718-0.748 in |

| 22 | 0.359-0.377 in | / | 0.813-0.843 in |

| 24 | 0.388-0.406 in | 0.622-0.652 in | 0.933-0.963 in |

| 28 | 0.388-0.406 in | 0.684-0.714in | 1.058-1.088 in |

| Order Number | Designation | Specifications | Quantity/ Box | Weight (kg)/box |

| 1 | RS906928 | 8-425 | 25500 | 19.00 |

| 2 | RS906929 | 13-425 | 12000 | 16.20 |

| 3 | RS906930 | 15-425 | 10000 | 15.20 |

| 4 | RS906931 | 18-400 | 6500 | 15.40 |

| 5 | RS906932 | 20-400 | 5500 | 17.80 |

| 6 | RS906933 | 22-400 | 4500 | 15.80 |

| 7 | RS906934 | 24-400 | 4000 | 14.60 |